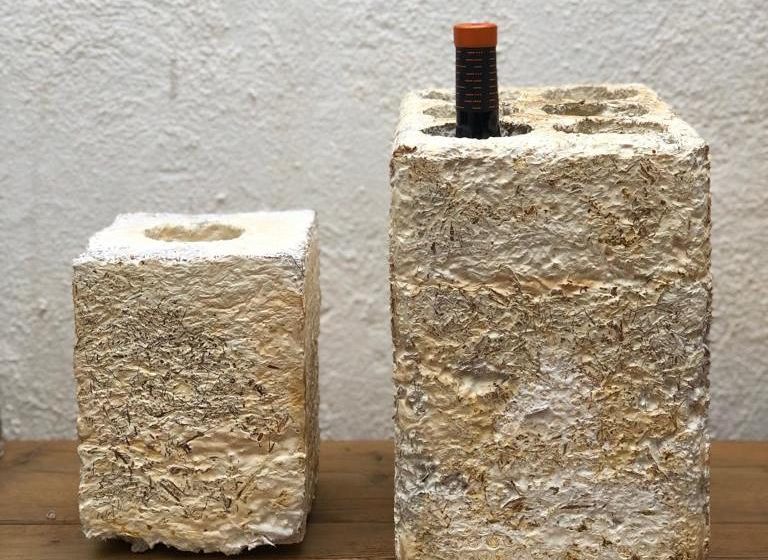

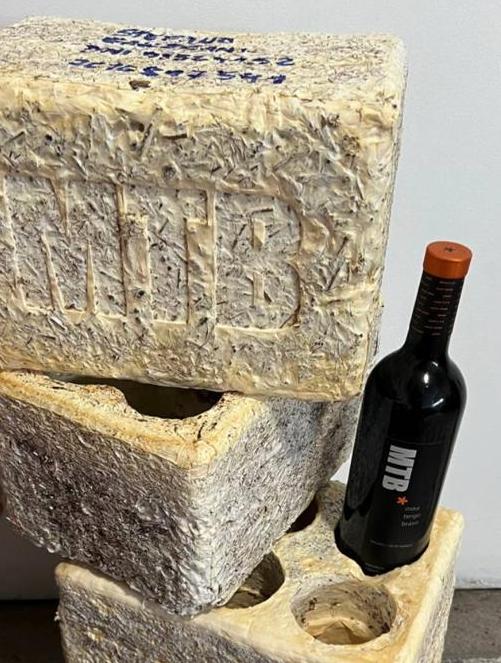

Mendoza wine producer Mike Tango Bravo has been scratching under the surface with his new wine packaging – using funghi to grow his own wine boxes. Taking prunings from his organic vineyard in Mendoza, the vine cuttings are shredded up and then placed in a mold with funghi (mycelium). These mycelia expand and grow to fit around vine cuttings and form a hard packaging – and, in Mike’s case, one which is ideal for carrying wine bottles.

“The idea behind the mycelium packaging is that you can sustainably grow your own in the winery from cuttings from the vineyard,” explains Mike, who has now made several prototypes of the packaging from his own vineyard. “By using your own vine cuttings and biomass, you are also sequestering carbon in your own packaging.”

Eco-friendly wine packaging from mushrooms and vineyard cuttings

Mycelium packaging is one of the most eco-friendly forms of packaging today. It requires no cardboard outer box, is 100% biodegradable and compostable, and is as hard as polystyrene (and much more eco-friendly). Importantly for wine, it is also an insulator.

“The other great thing about mycelium packaging is that it creates more thermal inertia, which is good for wine storage, especially when shipping long distances or overseas,” Mike adds.

Although mushroom packaging is already being used by some packaging companies and sold to wineries, what makes Mike’s project unique is that it is an initiative to create a community and share knowledge to allow wineries to make their own packaging.

“The idea is not to make a packaging company, and send packing around the world… It is for wineries to be able to grow their own packaging, from their own vineyards,” Mike explains. “What we are essentially aiming to create is an open-source model, which wineries can use for their own brand – but with the support of a community enabling them to grow their own packaging.”

Having worked with mycologists in Argentina to develop the prototypes over the past year and perfect the ‘grow your own’ process, Mike will soon be founding a DAO and recruiting other wineries to start growing their own wine boxes. The goal is to make it cheap and accessible for everyone to make their own packaging so that mycelium packaging can have a much bigger impact on the wine industry at large.

Currently, almost 40% of a winery’s carbon footprint is due to packaging, and this would make significant carbon savings. Wineries will also be able to certify their funghi packaging and carbon offset and emissions through Mike’s OpenVino platform. OpenVino is the world’s first open-source winery and wine-backed cryptocurrency, but it also hosts a biodigital certification platform on the blockchain – allowing sustainable initiatives to be verified and visible to all.

Could GYO be the future of wine packaging?

How does mycelium packaging work? And become a wine box? MTB explains

If you are interested in collaborating, contact Mike on Twitter @MTBcostaflores